Smart pump for commercial buildings with BMS.

With its optimised and innovative energy-saving functions, the Wilo-Stratos MAXO sets new standards in energy efficiency in HVAC and drinking water applications. It also enables extremely comfortable use thanks to its user-friendly features.

Features/Product benefits

- Different integration options for BMS

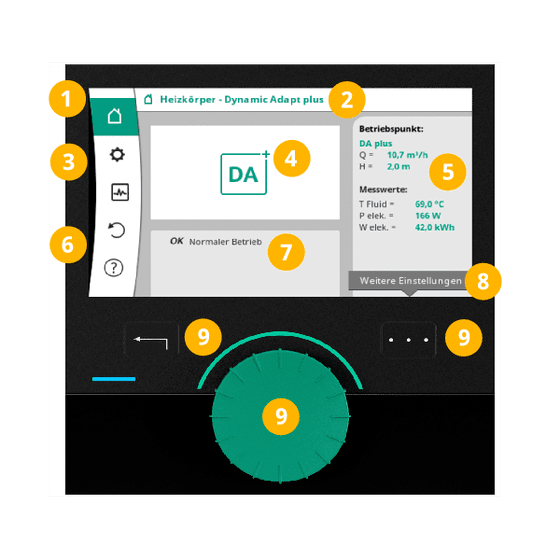

- In addition to application-oriented adjustments made with the settings assistant, the combination of new display features and the control knob with green button technology ensures easy operation.

- Highest energy efficiency thanks to the combination of optimised and innovative functions that save energy (e.g. No-Flow Stop).

- Optimum system efficiency thanks to intelligent and innovative control functions such as Dynamic Adapt plus, Multi-Flow Adaptation, T-const. and ΔT-const.

- State-of-the-art communication interfaces (e.g. Bluetooth) for connection to mobile end devices and direct pump networking via Wilo Net for multi-pump control.

- Maximum convenience in electrical installation thanks to the clear and large terminal compartment and the optimised Wilo-Connector.

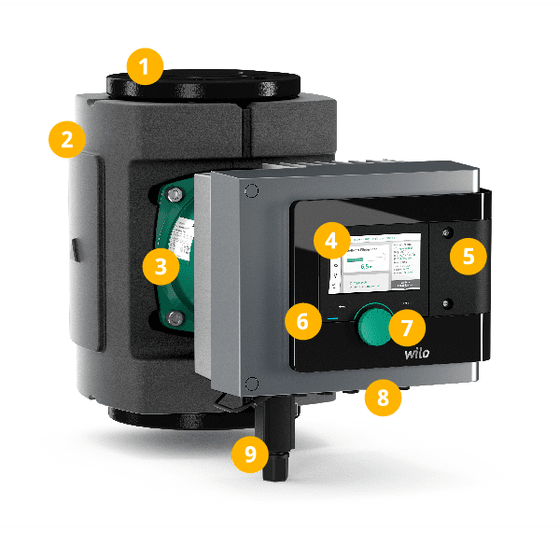

Construction

Intelligent wet rotor circulation pump with union connection or flange connection, EC motor with integrated electronic power adaptation.

APPLICATION

All systems hot water heating systems, air conditioning systems, closed cooling circuits, industrial circulation systems.

Hardware / function

Area of application

The pump enables operation with the highest system efficiency by precisely adjusting the control mode for a system-specific application (e.g. radiator, floor heating, ceiling cooling).

Heater

- Radiator

- Floor heating

- Ceiling heating

- Air heater

- Underfloor heating*

- Hydraulic shears

- Distributor without differential pressure*

- Heating buffer memory*

- Heat exchanger

- Heat source circuit (heat pump)*

- Remote heating circuit*

Cooling

- Ceiling cooling

- Floor cooling

- Air conditioning units

- Underfloor cooling*

- Hydraulic shears

- Distributor without differential pressure*

- Cooling buffer memory*

- Heat exchanger

- Recooling circuit*

- Remote cooling circuit*

(* System type is available as of SW≥01.05.10.00)

Combination of heating and cooling

- Automatic switching (model "-R7": not possible but with Stratos MAXO temperature sensor)

Depending on the selected application, the following control modes are available:

Control modes

- Constant speed (control mode)

- For constant differential pressure Δp-c

- Δp-v for variable differential pressure

- Dynamic Adapt plus feature for continuous (dynamic) adaptation of the pressing force according to the current need

- T-const for constant temperature regulation.

- ΔT-const for constant differential temperature regulation.

- Constant Q for constant flow regulation

- Multi-Flow Adaptation: Determining the total flow rate with the feed pump to ensure that secondary pumps in the heating circuit distributors feed as needed.

- User-defined PID regulation

Optional functions

- To limit the maximum flow rate Q-Limit max.

- To limit the minimum flow rate Q-Limit min.

- No-Flow Stop (Zero flow disable)

- Automatic setback operation ("-R7" model: not possible but with Stratos MAXO temperature sensor)

- Bad point regulation (Δp-c regulation with external actual value sensor)

- Variable slope of the Δp-v characteristic curve

Manual settings

- Application area selection in setting assistants

- Setting of operating parameters included

- Nominal operating point: Direct input of the calculated operating point in the Δp-v state

- Status indicator

- Setting and resetting the energy amount calculation (Heating and cooling)

- Air release function of the pump

- Key lock to lock settings

- Reset function to factory settings or saved recovery points (parameter sets)

- Parameterization of analog inputs

- Parameterization of binary data inputs

- Parameterization of relay outputs

- Twin pump function (2 single pumps that can operate as twin pumps)

Automatic functions

- Optimized power adaptation for low power consumption operation depending on the operating mode

- Setback operation detection (model "-R7": not possible but with Stratos MAXO temperature sensor)

- Deactivation when zero flow is detected (No-Flow Stop)

- Soft start

- Automatic debugging routines (e.g. deblocking function)

- Switching between heating/cooling operation ("-R7" model: automatic changeover not possible, but with Stratos MAXO temperature sensor)

- Full motor protection with integrated trip electronics

External control inputs and their functions

- 2x analog inputs:

- Signal types: 0 - 10 V, 2 - 10 V, 0 - 20 mA, 4 - 20 mA, PT1000

- Applications: Remote target value for each control mode setting (except Multi-Flow Adaptation), sensor inputs for temperature, differential pressure or free sensor in user-defined PID operation

- 2x digital inputs:

- For voltage-free control inputs or switches

- Parameterizable functions:

- ext.OFF

- ext.MIN

- ext.MAX

- MANUAL (BMS -OFF)

- Key lock

- Switching heating/cooling operation

Wilo Net for twin pump management of 2 single pumps, communication of multiple pumps with each other and remote pump adjustment via gateway

Signal and indicator functions

- Operation indicator display status:

- Target value

- Actual discharge head

- Actual flow rate

- Power consumption

- Electricity consumption

- Temperatures ("-R7" model: Actual fluid temperature possible with Stratos MAXO temperature sensor)

- Status indicator LED: Error-free operation (green LED), pump communication (blue LED)

- Error display status indicator (display color is red):

- Error code and error description in full text

- Stopping measures

- Warning screen status indicator (screen color yellow):

- Warning codes and full text of the warning's warning description

- Stopping measures

- Process indicator display status (display color blue):

- Pump air release

- Update process

- BMS communication display status (display color blue):

- Summary of active BMS parameters (data baud rate, address, ...)

- General fault signal SSM (voltage-free switchgear)

- General operating signal SBM (potential-free closing contact)

Data exchange

- Bluetooth interface for wireless data exchange and remote control operations between smartphone or tablet and pump.

- Remote monitoring of the pump with WiloCare

- Modbus TCP digital interface for connection to building automation (Wilo CIF module can be used with Ethernet (multi-protocol)).

- Modbus RTU serial digital interface for connection to building automation via RS485 BUS system (possible with Wilo-CIF-Modul Modbus RTU module).

- BACnet IP digital interface for connection to building automation (can be used with Wilo CIF module Ethernet (multi-protocol)).

- BACnet MS/TP serial digital interface for connection to building automation via RS485 BUS system (possible with Wilo-CIF-Modul BACnet MS/TP module).

- LON serial digital interface for connection to building automation via the LONWorks BUS system (possible with LON Wilo-CIF module).

- CANopen serial digital interface for connection to building automation via CANopen BUS system (possible with CANopen Wilo CIF module).

- PLR serial digital interface for connection to building automation via company-specific coupling module (possible with PLR Wilo-CIF module).

Twin pump management (twin pump or 2 x single pumps)

- Main/standby operation (automatic changeover in case of failure/timed pump changeover)

- Parallel operation (efficiency-optimized peak load switching on and off)

Hardware

- In flange pumps: Flange models

- Standard version for pumps DN 32 to DN 65: Combination flange PN 6/10 for counter flange PN 6 and PN 16 (flange PN 16 according to EN 1092-2)

- Standard version for DN 80 / DN 100 pumps: Flange PN 6 for counter flange PN 6 (designed for PN 16 according to EN 1092-2)

- Special version for pumps DN 32 to DN 100: Flange PN 16 for counter flange PN 16 (according to EN 1092-2)

- Many integrated communication interfaces and optional CIF module slot available

- 5 cable entries for connection of communication interfaces

- Bluetooth interface

- High resolution graphic display with green button and 2 keys

- User-friendly terminal compartment

- Integrated temperature sensor ("-R7" model: not available)

- Standard thermal insulation for heating systems applications

- Quick electrical connection with Wilo-Connector, optimised for electrical supply

Scope of delivery

- Pump

- Optimized Wilo-Connector

- 2x cable connection M16 x 1.5

- Seals in union connection

- Washers for flange connections (for nominal connection diameters DN 32 - DN 65)

- Thermal insulation jacket

- Installation and user manual

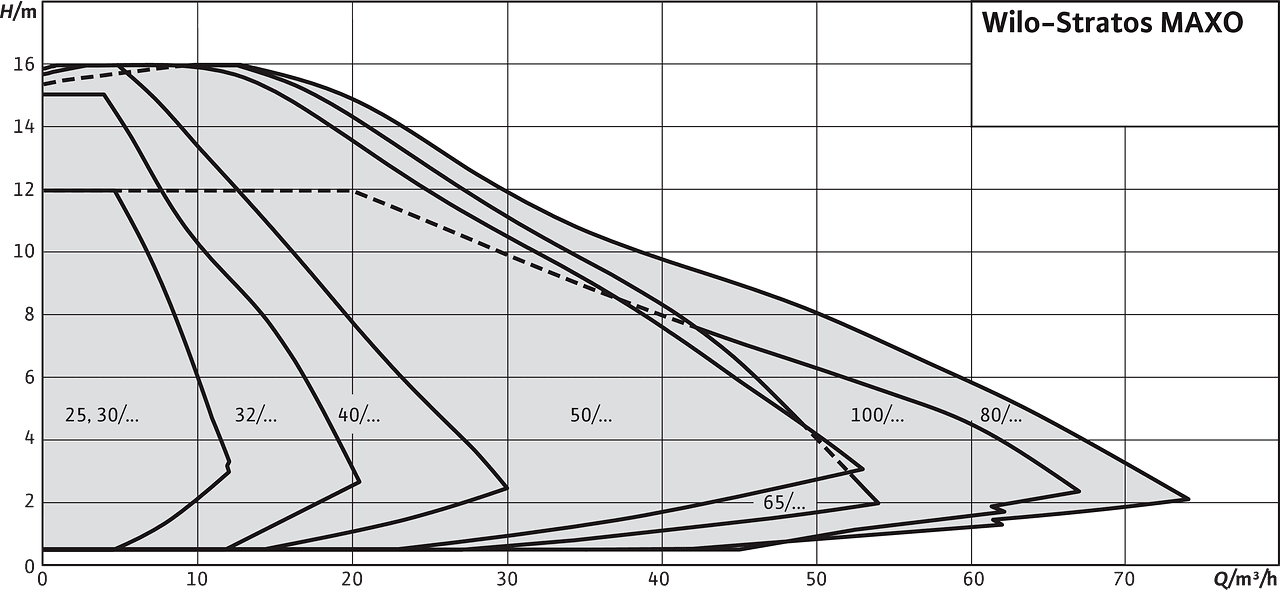

Type coding

Example: | Wilo-Stratos MAXO 30/0.5-12 |

Stratos MAXO | High efficiency pump (Pump with union or flange connection), electronically regulated |

30/ | Nominal connection diameter |

0.5-12 | Nominal pumping head range [m] |

-R7 | without integrated Stratos MAXO temperature sensor |

-P1 | LABS-free model |

Technical data

- Permissible temperature range -10 °C to +110 °C, -10 °C to +90 °C ("-R7" model)

- Mains connection 1~230 V, 50/60 Hz

- Protection class IPX4D

- Union or flange connection (depending on type) Rp 1 to DN 100

- Maximum operating pressure in standard version: 6/10 bar or 6 bar (special version: 10 bar or 16 bar)

- Insulation class: F

- Interference emission standard: EN 61800-3:2004+A1:2012 / Residential use (C1)

- Interference immunity standard: EN 61800-3:2004+A1:2012 / industrial use (C2)

- Flow rate max. Q : 74 m³/h

- Max. discharge head H : 16 m

Materials

- Bed: Coal, antimony impregnated

- Wheel: PPS-GF40

- Pump body: Cast iron

- Shaft: 1.4028, DLC coated

Design

- Intelligent wet rotor circulation pump with EC motor and integrated electronic power adjustment

- Green button technology and graphic display

- Trip electronic motor protection

- Connector for function expansion with optional CIF module for building automation

- Impeller with three-dimensional curved impeller blades and plastic rotor liner made of coal composite

| Select Model | : | Strassos MAXO |